CAN-BUS Shield V2.0

Introduction

CAN-BUS is a common industrial bus because of its long travel distance, medium communication speed and high reliability. It is commonly found on modern machine tools, such as an automotive diagnostic bus.

This CAN-BUS Shield adopts MCP2515 CAN Bus controller with SPI interface and MCP2551 CAN transceiver to give your Arduino/Seeeduino CAN-BUS capability. With an OBD-II converter cable added on and the OBD-II library imported, you are ready to build an onboard diagnostic device or data logger.

Previously we have made two versions of CAN-BUS Shield, the V1.0 and V1.2. They are all awesome shields that widely liked by our users. In order to make it better, several months ago we conducted a survey about CAN-BUS Shield V1.2 and received many valuable advices (Thanks to all the users who replied to us), so we decided to make an update and here it is - CAN-BUS Shield V2.

Version

This document applies to the following version of products:

| Version | Released Date | How to Buy |

|---|---|---|

| CAN BUS Shield V1.0 | Oct 14, 2012 |  |

| CAN BUS Shield V1.1 | Aug 10, 2013 |  |

| CAN BUS Shield V1.2 | Jan 05, 2015 |  |

| CAN BUS Shield V2.0 | Aug 01,2017 |  |

Version Tracker

| Features | V1.2 | V2.0 |

|---|---|---|

| CAN-BUS Controller | MCP2515 | MCP2515 |

| CAN Transceiver | MCP2551 | MCP2551 |

| Default OBD Pinout | OBD-II Standard | OBD-II Standard |

| CAN Standard Pinout | Not compatible | Compatible (jumper) |

| INT Pin | Not changeable | D2 or D3 (jumper) |

| CS pin for TF card slot | No TF card slot | D4 or D5 (jumper) |

| Serial Grove | D0/D1 | A0/A1 |

| I2C Grove | A4/A5 | SDA/SCL |

| Grove Orientation | Vertical | Horizontal |

| P1 pad | Front of the shied | Back of the shield |

What’s new in CAN BUS Shield V2.0

Hardware

- OBD-II or CAN standard pinout can be selected by switching jumpers on DB9 interface, the default pinout is OBD-II.

- Add a TF card slot for data storage and the CS pin can be either set to D4 or D5.

- The INT pin can be set to D2 or D3 by switching jumpers on the back of the shield.

- Moved the P1 pad from front to the back of the shield to make it easier to cut and solder.

- Consider that the D0/D1 pin are usually used for downloading code, we changed the serial Grove connector to pin A0/A1.

- The I2C grove connector is also changed to more reasonable standard SDA/SCL pin instead of previous A4/A5.

- The two grove connectors are both changed to horizontal rather than vertical to the shield so that it would be more convenient when connecting to other grove modules.

Software

- Add the function and example to access the data of your car.

- Add the function to read the SD card.

- Add the example to store the data of your car into the SD card.

- Fix some bugs and optimize some program.

D-Sub CANbus PinOut

| pin# | Signal names | Signal Description |

|---|---|---|

| 1 | Reserved | Upgrade Path |

| 2 | CAN_L | Dominant Low |

| 3 | CAN_GND | Ground |

| 4 | Reserved | Upgrade Path |

| 5 | CAN_SHLD | Shiled, Optional |

| 6 | GND | Ground,Optional |

| 7 | CAN_H | Dominant High |

| 8 | Reserved | Upgrade Path |

| 9 | CAN_V+ | Power, Optional |

Alternative Choice

If your project is space limited and also don’t need other fuctions except CAN-BUS, here is a Grove CAN-BUS module which is Arduino compatible, more compact and cost effective, please click here to visit its page.

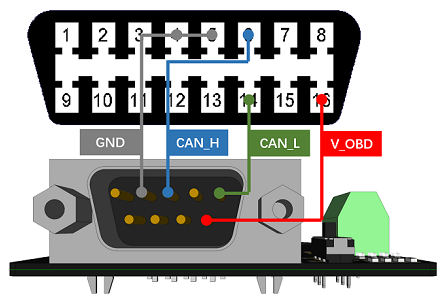

What if I want to connect this shield to my car

If you want to read data or control your car, there’s an OBD>DB9 cable available for you, this cable make easier to connect to OBD-connector and DB9-connector. This cable will also work with anything that has a OBD-connector. Add a power switch makes such a satisfying click.

USB-CAN Analyzer

If you want a CAN Bus Analyzer to debug your CAN Bus, this USB-CAN Analyzer is recommended.

Features

- Implements CAN V2.0B at up to 1 Mb/s

- Industrial standard 9 pin sub-D connector

- OBD-II and CAN standard pinout selectable.

- Changeable chip select pin

- Changeable CS pin for TF card slot

- Changeable INT pin

- Screw terminal that easily to connect CAN_H and CAN_L

- Arduino Uno pin headers

- 2 Grove connectors (I2C and UART)

- SPI Interface up to 10 MHz

- Standard (11 bit) and extended (29 bit) data and remote frames

- Two receive buffers with prioritized message storage

Note

CAN BUS Shield Work well with Arduino UNO (ATmega328), Arduino Mega (ATmega1280/2560) as well as Arduino Leonardo (ATmega32U4).

Hardware Overview

- DB9 Interface - to connect to OBDII Interface via a DBG-OBD Cable.

- V_OBD - It gets power from OBDII Interface (from DB9)

- Led Indicator:

- PWR: power

- TX: blink when the data is sending

- RX: blink when there’s data receiving

- INT: data interrupt

- Terminal - CAN_H and CAN_L

- Arduino UNO pin out

- Serial Grove connector

- I2C Grove connector

- ICSP pins

- IC - MCP2551, a high-speed CAN transceiver (datasheet)

- IC - MCP2515, stand-alone CAN controller with SPI interface (datasheet)

- SD card slot

Warning

When you use more than two CAN Bus Shield in one net, you should take the impedance into consideration. You should either cut P1 in the PCB with a knife, or just remove R3 on the PCB.

Pin map

Note

- The FREE pin is available for the other usages.

DB9&OBDii Interface

CS_CAN pin

SPI_CS pin of V2.0 is connected to D9 by default. If you want to change to D10, please follow below instructions.

- Step1: Take a look at the backside of the PCBA, you will find a pad named CS_CAN.

- Step2: Cut the wire between pad9 and the middle pad.

- Step3:Weld the middle pad and pad 10.

Warning

Be careful with the box cutter, it’s easy to hurt yourself or the PCBA.

INT pin

INT pin of V2.0 is connected to D2 by default. If you want to change to D3, please follow below instructions.

- Step1: Take a look at the backside of the PCBA, you will find a pad named INT.

- Step2: Cut the wire between pad 2 and the middle pad.

- Step3:Weld the middle pad and pad 3.

SPI pins

The SPI pins (SCK, MISO, MOSI) are routed to the ICSP pins by default. But for some boards, the SPI pins are located at D11~D13. if this happens, you need make some change to the PCBA. Take a look at the backside of the PCBA, there’re three pads, MOSI, MISO and SCK, they are connected to A by default. You can change them to B if needed.

Note

For Arduino UNO, Arduino Mega, Arduino Leonardo and any others AVR based Arduino boards, it works well by default setting.

Warning

Be careful when you are going to change SPI pins, it’s easy to hurt yourself or the PCBA.

Getting Started

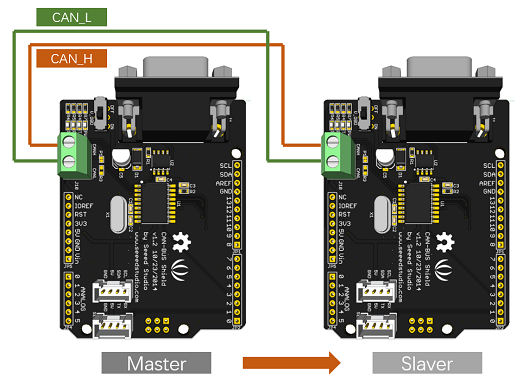

Here’s a simple example to show you how CAN-BUS Shield works. In this example we need 2 pieces of CAN-BUS Shields as well as Arduino or Seeeduino.

Note

This example is built under Arduino IDE version 1.6.9.

STEP1: What do we need

| Name | Function | Qty | Link |

|---|---|---|---|

| CAN-BUS Shield | CAN Bus communication | 2 | link |

| Seeeduino V4.2 | Controller | 2 | link |

| Jumper Wire | connection | 2 | link |

STEP2: Hardware Connection

Insert each CAN-BUS Shield into Seeeduino V4.2, and connect the 2 CAN-BUS Shield together via 2 jumper wires. Shown as below images.

Note

CAN_H to CAN_H, CAN_L to CAN_L

STEP3: Software

Please follow how to install an arduino library procedures to install CAN BUS shield library.

Click on below button to download the library.

Install the library to your Arduino IDE when it is downloaded.

One of the node (a node means Seeeduino + CAN_BUS Shield) acts as master, the other acts as slaver. The master will send data to slaver constantly.

Note

Each node can act as master before the code being uploaded.

Open the send example (File > Examples > CAN_BUS_Shield-master > send) and upload to the master.

Open the receive_check example (File > Examples > CAN_BUS_Shield-master > receive_check) and upload to the slaver.

Open the receive_check example (File > Examples > CAN_BUS_Shield-master > receive_check) and upload to the slaver.

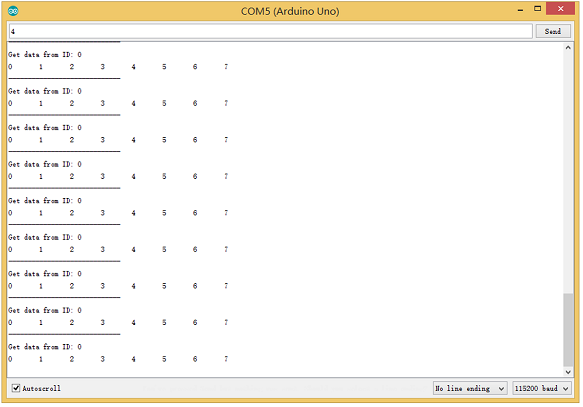

STEP4: View Result

Open the Serial Monitor of Arduino IDE(slaver), you will get the data sent from the master.

APIs

1. Set the Baud rate

This function is used to initialize the baud rate of the CAN Bus system.

The available baud rates are listed as follows:

#define CAN_5KBPS 1

#define CAN_10KBPS 2

#define CAN_20KBPS 3

#define CAN_25KBPS 4

#define CAN_31K25BPS 5

#define CAN_33KBPS 6

#define CAN_40KBPS 7

#define CAN_50KBPS 8

#define CAN_80KBPS 9

#define CAN_83K3BPS 10

#define CAN_95KBPS 11

#define CAN_100KBPS 12

#define CAN_125KBPS 13

#define CAN_200KBPS 14

#define CAN_250KBPS 15

#define CAN_500KBPS 16

#define CAN_666kbps 17

#define CAN_1000KBPS 18

2. Set Receive Mask and Filter

There are 2 receive mask registers and 5 filter registers on the controller chip that guarantee you getting data from the target device. They are useful especially in a large network consisting of numerous nodes.

We provide two functions for you to utilize these mask and filter registers. They are:

Mask:

init_Mask(unsigned char num, unsigned char ext, unsigned char ulData);

Filter:

init_Filt(unsigned char num, unsigned char ext, unsigned char ulData);

- num represents which register to use. You can fill 0 or 1 for mask and 0 to 5 for filter.

- ext represents the status of the frame. 0 means it’s a mask or filter for a standard frame. 1 means it’s for a extended frame.

- ulData represents the content of the mask of filter.

3. Check Receive

The MCP2515 can operate in either a polled mode, where the software checks for a received frame, or using additional pins to signal that a frame has been received or transmit completed.

Use the following function to poll for received frames.

INT8U MCP_CAN::checkReceive(void);

The function will return 1 if a frame arrives, and 0 if nothing arrives.

4. Get CAN ID

When some data arrive, you can use the following function to get the CAN ID of the “send” node.

INT32U MCP_CAN::getCanId(void)

5. Send Data

CAN.sendMsgBuf(INT8U id, INT8U ext, INT8U len, data_buf);

It is a function to send data onto the bus. In which:

- id represents where the data comes from.

- ext represents the status of the frame. ‘0’ means standard frame. ‘1’ means extended frame.

- len represents the length of this frame.

- data_buf is the content of this message.

For example, In the ‘send’ example, we have:

unsigned char stmp[8] = {0, 1, 2, 3, 4, 5, 6, 7};

CAN.sendMsgBuf(0x00, 0, 8, stmp); //send out the message 'stmp' to the bus and tell other devices this is a standard frame from 0x00.

6. Receive Data

The following function is used to receive data on the ‘receive’ node:

CAN.readMsgBuf(unsigned char len, unsigned char buf);

In conditions that masks and filters have been set. This function can only get frames that meet the requirements of masks and filters.

- len represents the data length.

- buf is where you store the data.

Generate a New BaudRate

We had provided many frequently-used baud rates, as below:

#define CAN_5KBPS 1

#define CAN_10KBPS 2

#define CAN_20KBPS 3

#define CAN_25KBPS 4

#define CAN_31KBPS 5

#define CAN_33KBPS 6

#define CAN_40KBPS 7

#define CAN_50KBPS 8

#define CAN_80KBPS 9

#define CAN_83KBPS 10

#define CAN_95KBPS 11

#define CAN_100KBPS 12

#define CAN_125KBPS 13

#define CAN_200KBPS 14

#define CAN_250KBPS 15

#define CAN_500KBPS 16

#define CAN_666KBPS 17

#define CAN_1000KBPS 18

Yet you may still can’t find the rate you want. Here we provide a software to help you to calculate the baud rate you need.

Click here to download the software, it’s in Chinese, but never mind, it’s easy to use.

Note

This software supports Windows system only. If you can’t open it, please feel free to contact loovee@seeed.cc for support.

Open the software, what you need to do is to set the baud rate you want, and then do some simple setting, then click calculate.

Then you will get some data, cfg1, cfg2 and cfg3.

You need to add some code to the library.

Open mcp_can_dfs.h, you need to add below code at about line 272:

#define MCP_16MHz_xxxkBPS_CFG1 (cfg1) // xxx is the baud rate you need

#define MCP_16MHz_xxxkBPS_CFG2 (cfg2)

#define MCP_16MHz_xxxkBPS_CFG3 (cfg2)

Then let’s go to about line 390, add below code:

#define CAN_xxxKBPS NUM // xxx is the baudrate you need, and NUM is a number, you need to get a different from the other rates.

Open mcp_can.cpp, goto the function mcp2515_configRate(at about line 190), then add below code:

case (CAN_xxxKBPS):

cfg1 = MCP_16MHz_xxxkBPS_CFG1;

cfg2 = MCP_16MHz_xxxkBPS_CFG2;

cfg3 = MCP_16MHz_xxxkBPS_CFG3;

break;

Then you can use the baud rate you need. And please give me a pull request at github when you use a new rate, so I can add it to the library to help other guys.

Projects

If you want to make some awesome projects with CAN-BUS shield, here are some projects for reference.

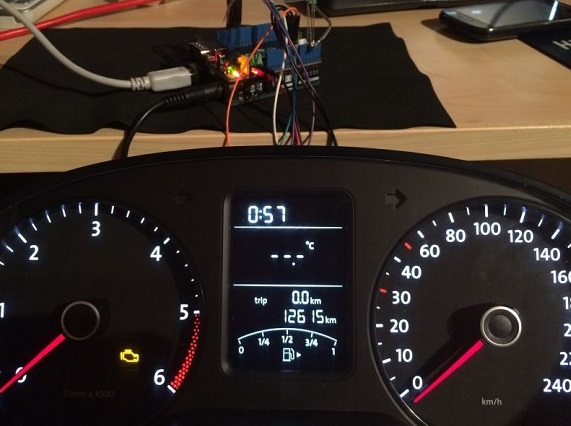

Volkswagen CAN BUS Gaming

Ever wanted to play a car/truck simulator with a real dashboard on your PC? Me too! I’m trying to control a VW Polo 6R dashboard via CAN Bus with an Arduino Uno and a Seeed CAN Bus Shield. Inspired by Silas Parker. Thanks Sepp and Is0-Mick for their great support!

Hack your vehicle CAN-BUS

Modern Vehicles all come equipped with a CAN-BUS Controller Area Network, Instead of having a million wires running back and forth from various devices in your car to the battery, its making use of a more clever system.

All electronic functions are connected to the TIPM, (Totally integrated Power Module), such as solenoids/relays to lock the doors or mini motors to wind the windows etc.

From each node (IE Switch pod that controls your windows or electric door locks) it broadcasts a message across the CAN. When the TIPM detects a valid message it will react accordingly like, lock the doors, switch on lights and so on.

FAQ

Q1: I can’t get data from other CAN device.

- Check if the connection is right

- Check if the baud rate setting is right

Q2: The serial monitor print Init Fail.

- Check if the CS pin setting is matched with the code. For CAN Bus Shield V1.1/1.2, CS pin is connected to D9, others are to D10.

Q3. Where can I find technical support if I have some other issues.

- You can post a question to Seeed Forum or send an email to techsupport@seeed.cc.

Resources

- 【PDF】CAN-BUS Shield V2.0 Schmatics

- 【Eagle】Schematic & PCB of CAN-BUS Shield V2.0

- 【Library】Arduino Library for CAN-BUS Shield

- 【Datasheet】MCP2515 datasheet

- 【Datasheet】MCP2551 datasheet

- 【Demo】An OBD Demo

- 【Tool】MCP2515 Baud Rate Tool

- 【Tool】USB-CAN Analyzer

- 【Cable】DB9 to OBD2 Cable

Help us make it better

Welcome to the new documentation system of Seeed Studio. We have made a lot of progress comparing to the old wiki system and will continue to improve it to make it more user friendly and helpful. The improvement can't be done without your kindly feedback. If you have any suggestions or findings, you are most welcome to submit the amended version as our contributor via Github or give us suggestions in the survey below, it would be more appreciated if you could leave your email so that we can reply to you. Happy Hacking!